All factories of our group have set the comprehensive ESH management system based on ISO14001&ISO45001,regularly conduct environment impact assessment , HS risk assessment and conduct a comprehensive analysis of the potential impacts of production activities on the surrounding ecosystem, including wastewater discharge, energy consumption, waste disposal, and noise control, while identifying potential hazard source in production processes, workplace, and equipment facilities, upholding continuous improvement principle to reduce the risk on environment, health and safety to an acceptable level.

Each factory has established a specialized ESH (Environment, Safety & Health) Management Committee, which convenes monthly ESH meetings. During these sessions, Management representative and employee representative discuss emerging issues and challenges such like equipment safety hazards reported by workshop workers or ESH KPI presented by administrative departments. The factory's ESH team subsequently develops detailed corrective action plan for the items requiring improvement based on meeting resolutions and advances it.

The Group adheres to the "Double Zero" target, ensuring that the company's ESH management not only complies with but even exceeds local laws, regulations, and customer requirements. The Group is also committed to advancing the development of a safety culture, encouraging all employees to actively participate in the daily management of ESH and various activities, creating a more environmentally friendly, safe, and healthy working and living environment.

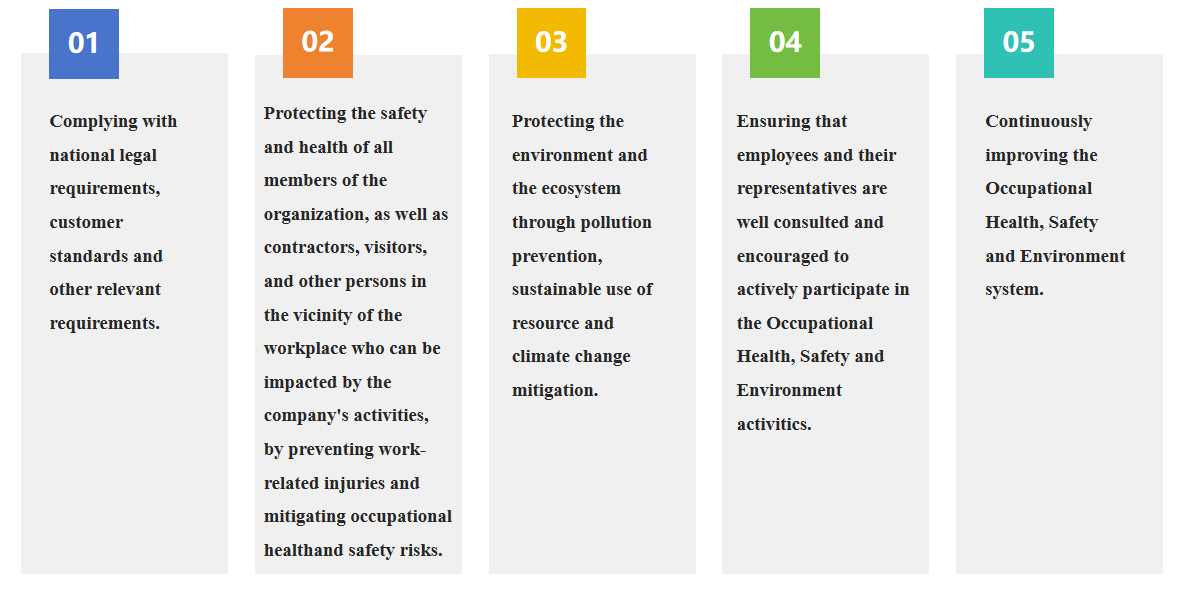

we hereby commit to the following key principles and objectives:

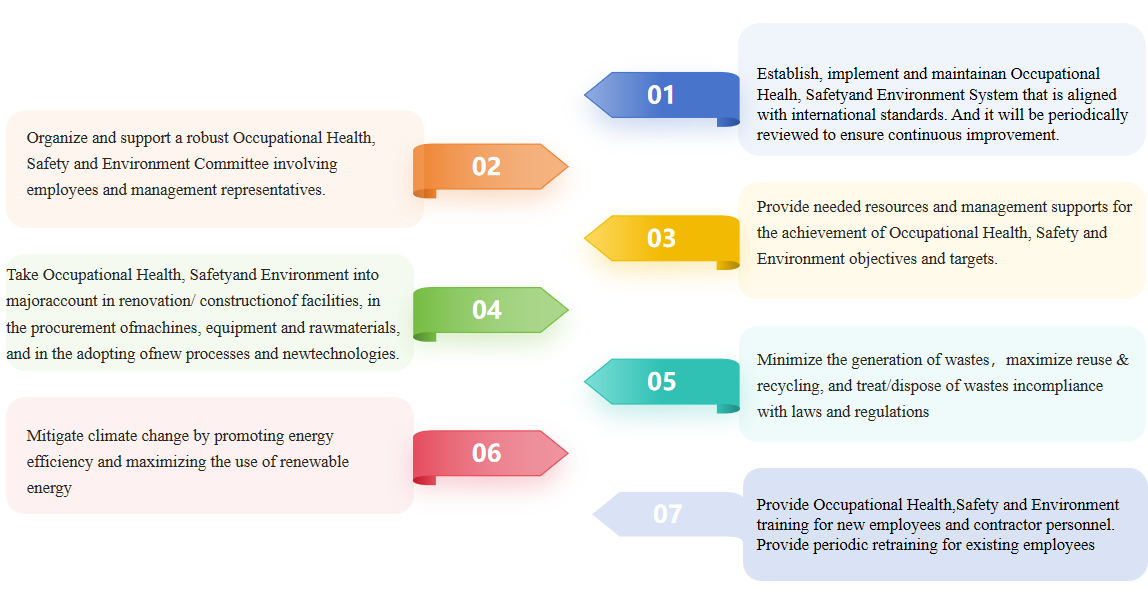

To meet our commitments, we shall:

More